Product Description

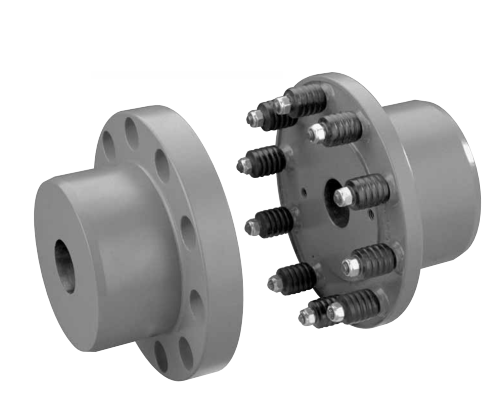

GCLD gear coupling Drum toothed coupling

Description:

GCLD series of drum gear coupling, especially suitable for low speed and heavy load conditions, such as metallurgy, mining, lifting and transportation industries, also suitable for petroleum, chemical, general machinery and other machinery shafting transmission.Characteristics of drum gear coupling (compared with straight gear coupling, it has the following characteristics).

Parameters:

Norminal Torque: 0.4kN. M – 4500kN. M

Allowed Rotation Speed: 4000rpm -460rpm

Connection: Keyway & Shaft hole

Shaft Hole Diameter: 16mm – 1040mm

Shaft Hole Length (Y): 42mm – 1100mm

Advantages:

1. The bearing capacity is strong.

2. Large amount of angular displacement compensation

3. The drum shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration at the straight tooth end under the condition of angular displacement, improves the friction and wear condition of the tooth surface, reduces the noise, and has a long maintenance cycle;

4. The tooth end of the outer tooth sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth very convenient.

5. The transmission efficiency is as high as 99.7%.

Packing & Delivery:

Applications:

Metallurgy, mining, lifting and transportation industries, petroleum, chemical, general machinery and other heavy machinery shaft drive.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Bore Diameter: | 19mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Types of Pin Coupling Designs

Pin couplings, also known as shear pin couplings, come in various designs to suit different application requirements. The main types of pin coupling designs are as follows:

- 1. Single Pin Coupling: In this design, a single shear pin is used to connect the two shafts. The pin is placed in a hole that runs through both coupling halves. Under excessive torque or shock loads, the pin shears off, disconnecting the shafts and protecting the equipment from damage. Single pin couplings are commonly used in light to moderate-duty applications.

- 2. Double Pin Coupling: Double pin couplings use two shear pins that are positioned 180 degrees apart. This design provides increased torque capacity and improved balance compared to the single pin design. Double pin couplings are suitable for applications with higher torque requirements.

- 3. Triangular Pin Coupling: Triangular pin couplings use three pins arranged in a triangular pattern around the circumference of the coupling. This design offers even higher torque capacity and improved torsional stiffness. Triangular pin couplings are ideal for heavy-duty applications where higher torque and misalignment tolerance are essential.

- 4. Splined Pin Coupling: Splined pin couplings use splines instead of solid pins to transmit torque between the shafts. The splines provide a more secure connection and better torque transmission compared to solid pins. Splined pin couplings are commonly used in precision motion control applications.

- 5. Taper Pin Coupling: Taper pin couplings use tapered pins that wedge tightly into matching tapered holes in the coupling halves. This design offers excellent torque transmission and alignment capabilities. Taper pin couplings are often used in heavy machinery and power transmission systems.

Each type of pin coupling design has its advantages and limitations, and the selection depends on factors such as the application’s torque requirements, misalignment tolerance, and environmental conditions. It is essential to choose the right type of pin coupling to ensure optimal performance, reliability, and safety in the mechanical system.

editor by CX 2024-05-08

China Huading Pgclz Type Drum Shape Gear Coupling with Brake Disc Couplings coupling bearing

Product Description

PGCLZ Drum Gear Coupling with Brake Disc (Q/LZP02.03-2005)

♦Description

Drum gear type coupling belongs to rigid flexible coupling, equipment variety coupling is composed of inner gear ring and flange 50 % coupling with outer equipment with identical amount of enamel.Can increase the contact situations of enamel, boost the potential to transfer torque, extend the services life.Radial, axial and angular axis deviation compensation capacity, has a compact composition, small turning radius, huge carrying capacity, large transmission efficiency, low sounds and lengthy maintenance cycle, specially appropriate for the condition of minimal pace and hefty loading, this sort of as metallurgy, mining, lifting transportation and other industries, can also be used to petroleum, chemical market, common machinery and other varieties of shaft transmission of device.

♦Main Dimension and Parameter(Q/LZP02.03-2005)

| Type | Nominal Torque Tn/(N·m) |

Allowable Pace (n)/(r/min) |

Bore Diameter d1d2dz |

Bore Duration (L) |

D | D | Done | D2 | D3 | L | T | C1 | Ctwo | e | Grease dosage(v) mL |

Mess (m) kg |

Rotary inertia(l) L/(kg·mtwo) |

||

| Pushed | Generate | Y | J1Zone | ||||||||||||||||

| PGCLZ1 | 630 | 4000 | twenty | 24 | fifty two | 38 | 315 | 125 | ninety five | 60 | 80 | 90 | thirty | twenty five | 39 | 30 | sixty | five.four | .01 |

| PGCLZ2 | 1120 | 4000 | 25 | 28 | 62 | forty four | 315 | a hundred and forty four | one hundred twenty | seventy five | ninety five | a hundred and five | thirty | twenty five.5 | forty four | thirty | 110 | nine.two | .02 |

| PGCLZ3 | 2240 | 3550 | 30 | 38 | eighty two | sixty | 355 | 174 | one hundred forty | 95 | one hundred fifteen | one hundred thirty | 30 | eighteen | forty | 30 | one hundred fifty five | sixteen.4 | .04 |

| PGCLZ4 | 3550 | 2500 | 32 | 38 | eighty two | sixty | forty | 196 | one hundred sixty five | a hundred and fifteen | 130 | one hundred thirty | thirty | 29 | 47 | thirty | 190 | 22.seven | .08 |

| PGCLZ5 | 5000 | 2500 | forty | fifty six | 112 | 84 | 400 | 224 | 183 | one hundred thirty | one hundred fifty | one hundred fifty | thirty | 18 | forty three | thirty | 300 | 36.2 | .fifteen |

| PGCLZ6 | 7100 | 2000 | 48 | 56 | 112 | 84 | 450 | 241 | two hundred | 145 | 170 | a hundred and fifty five | thirty | 21 | 50 | thirty | 420 | forty six.2 | .24 |

| PGCLZ7 | ten thousand | 1700 | 60 | seventy five | 142 | 107 | 450 | 265 | 230 | one hundred sixty | one hundred ninety | 180 | thirty | 19 | fifty | 30 | 630 | 68.4 | .forty three |

| PGCLZ8 | 14000 | 1700 | 65 | 75 | 142 | 107 | 500 | 285 | 245 | a hundred seventy five | 210 | one hundred eighty | 30 | 20 | fifty | 30 | 730 | 81.one | .sixty one |

| PGCLZ9 | 18000 | 1600 | 70 | 75 | 142 | 107 | 560 | 314 | 270 | 200 | 225 | 200 | thirty | 25 | 60 | 30 | 770 | a hundred.one | .ninety four |

| PGCLZ10 | 31500 | 1600 | eighty | ninety five | 172 | 132 | 800 | 346 | 300 | 220 | 250 | 230 | thirty | 20 | 58 | thirty | 990 | 147.1 | one.sixty seven |

| PGCLZ11 | 40000 | 1400 | 100 | one hundred twenty | 212 | 167 | 800 | 385 | 330 | 260 | 285 | 260 | thirty | 21 | sixty four | forty | 1300 | 206.three | 2.98 |

| PGCLZ12 | 56000 | 1400 | – | a hundred and twenty | 212 | 167 | 900 | 442 | 380 | 290 | 325 | 280 | 30 | 21 | 72 | forty | 2200 | 284.5 | 5.31 |

| PGCLZ13 | 80000 | 1400 | 140 | a hundred and fifty | 252 | 202 | 900 | 482 | 420 | 320 | 360 | 320 | thirty | 22 | 70 | forty | 3300 | 402 | nine.16 |

| PGCLZ14 | 112000 | 1200 | 160 | a hundred and eighty | 302 | 242 | 900 | 520 | 465 | 360 | 410 | 360 | 30 | 23 | 85 | forty | 4900 | 582.2 | 15.92 |

Observe:

one. The mass and minute of inertia of the coupling are approximate values calculated in accordance to the minimum shaft gap diameter and highest shaft gap size in every single kind

two. The highest braking torque Tm of the coupling shall not exceed 2 times of the nominal torque Tn, that is, Tm≤2Tn

three. e is the dimensions essential for sealing

4. The blend of coupling shaft hole is Z1/J1, Y/Y, J1/J1, Y/J1.

♦Other Items Record

| Transmission Machinery Elements Identify |

Model |

| Common Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| Substantial Adaptable Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Organization

Our company supplies various types of products. Substantial high quality and sensible price. We stick to the basic principle of “top quality very first, provider first, ongoing enhancement and innovation to satisfy the clients” for the management and “zero defect, zero issues” as the quality objective. To perfect our support, we provide the products with very good high quality at the sensible price.

Welcome to customize merchandise from our manufacturing unit and remember to give your design drawings or get in touch with us if you want other needs.

♦Our Providers

one.Design and style Companies

Our design and style group has expertise in cardan shaft relating to solution style and growth. If you have any demands for your new solution or desire to make further enhancements, we are here to offer you our help.

two.Item Solutions

Uncooked components → Slicing → Forging →Rough machining →Shot blasting →Heat remedy →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Delivery

3.Samples Process

We could produce the sample according to your prerequisite and amend the sample consistently to satisfy your want.

four.Research & Growth

We typically study the new demands of the market place and build the new design when there is new vehicles in the market.

five.High quality Control

Every stage should be specific check by Expert Personnel in accordance to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you investing firm or maker?

A: We are a skilled manufacturer specializing in manufacturing various collection of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the consumers with personalized artworks of PDF or AI structure.

Q 3: How lengthy is your supply time?

Generally it is 20-30 days if the merchandise are not in inventory. It is in accordance to quantity.

Q 4: Do you supply samples? Is it cost-free or extra ?

Indeed, we could offer you the sample but not for free.Actually we have a extremely very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How lengthy is your warranty?

A: Our Warranty is 12 months beneath typical circumstance.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection techniques for coupling ?

A: a hundred% self-inspection prior to packing.

Q 8: Can I have a go to to your manufacturing facility before the buy?

A: Positive,welcome to visit our manufacturing facility.

Q 9: What is your payment?

A: T/T.

♦Contact Us

Internet: huadingcoupling

Incorporate: No.11 HangZhou Highway,Chengnan park,HangZhou Metropolis,ZheJiang Province,China

|

/ Piece | |

1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | as Required |

| Torque: | as Required |

| Bore Diameter: | as Required |

| Speed: | as Required |

| Structure: | Flexible |

###

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Type | Nominal Torque Tn/(N·m) |

Allowable Speed (n)/(r/min) |

Bore Diameter d1d2dz |

Bore Length (L) |

D0 | D | D1 | D2 | D3 | L0 | T | C1 | C2 | e | Grease dosage(v) mL |

Mess (m) kg |

Rotary inertia(l) L/(kg·m2) |

||

| Driven | Drive | Y | J1Z1 | ||||||||||||||||

| PGCLZ1 | 630 | 4000 | 20 | 24 | 52 | 38 | 315 | 125 | 95 | 60 | 80 | 90 | 30 | 25 | 39 | 30 | 60 | 5.4 | 0.01 |

| PGCLZ2 | 1120 | 4000 | 25 | 28 | 62 | 44 | 315 | 144 | 120 | 75 | 95 | 105 | 30 | 25.5 | 44 | 30 | 110 | 9.2 | 0.02 |

| PGCLZ3 | 2240 | 3550 | 30 | 38 | 82 | 60 | 355 | 174 | 140 | 95 | 115 | 130 | 30 | 18 | 40 | 30 | 155 | 16.4 | 0.04 |

| PGCLZ4 | 3550 | 2500 | 32 | 38 | 82 | 60 | 40 | 196 | 165 | 115 | 130 | 130 | 30 | 29 | 47 | 30 | 190 | 22.7 | 0.08 |

| PGCLZ5 | 5000 | 2500 | 40 | 56 | 112 | 84 | 400 | 224 | 183 | 130 | 150 | 150 | 30 | 18 | 43 | 30 | 300 | 36.2 | 0.15 |

| PGCLZ6 | 7100 | 2000 | 48 | 56 | 112 | 84 | 450 | 241 | 200 | 145 | 170 | 155 | 30 | 21 | 50 | 30 | 420 | 46.2 | 0.24 |

| PGCLZ7 | 10000 | 1700 | 60 | 75 | 142 | 107 | 450 | 265 | 230 | 160 | 190 | 180 | 30 | 19 | 50 | 30 | 630 | 68.4 | 0.43 |

| PGCLZ8 | 14000 | 1700 | 65 | 75 | 142 | 107 | 500 | 285 | 245 | 175 | 210 | 180 | 30 | 20 | 50 | 30 | 730 | 81.1 | 0.61 |

| PGCLZ9 | 18000 | 1600 | 70 | 75 | 142 | 107 | 560 | 314 | 270 | 200 | 225 | 200 | 30 | 25 | 60 | 30 | 770 | 100.1 | 0.94 |

| PGCLZ10 | 31500 | 1600 | 80 | 95 | 172 | 132 | 800 | 346 | 300 | 220 | 250 | 230 | 30 | 20 | 58 | 30 | 990 | 147.1 | 1.67 |

| PGCLZ11 | 40000 | 1400 | 100 | 120 | 212 | 167 | 800 | 385 | 330 | 260 | 285 | 260 | 30 | 21 | 64 | 40 | 1300 | 206.3 | 2.98 |

| PGCLZ12 | 56000 | 1400 | – | 120 | 212 | 167 | 900 | 442 | 380 | 290 | 325 | 280 | 30 | 21 | 72 | 40 | 2200 | 284.5 | 5.31 |

| PGCLZ13 | 80000 | 1400 | 140 | 150 | 252 | 202 | 900 | 482 | 420 | 320 | 360 | 320 | 30 | 22 | 70 | 40 | 3300 | 402 | 9.16 |

| PGCLZ14 | 112000 | 1200 | 160 | 180 | 302 | 242 | 900 | 520 | 465 | 360 | 410 | 360 | 30 | 23 | 85 | 40 | 4900 | 582.2 | 15.92 |

###

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

|

/ Piece | |

1 Piece (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | as Required |

| Torque: | as Required |

| Bore Diameter: | as Required |

| Speed: | as Required |

| Structure: | Flexible |

###

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Type | Nominal Torque Tn/(N·m) |

Allowable Speed (n)/(r/min) |

Bore Diameter d1d2dz |

Bore Length (L) |

D0 | D | D1 | D2 | D3 | L0 | T | C1 | C2 | e | Grease dosage(v) mL |

Mess (m) kg |

Rotary inertia(l) L/(kg·m2) |

||

| Driven | Drive | Y | J1Z1 | ||||||||||||||||

| PGCLZ1 | 630 | 4000 | 20 | 24 | 52 | 38 | 315 | 125 | 95 | 60 | 80 | 90 | 30 | 25 | 39 | 30 | 60 | 5.4 | 0.01 |

| PGCLZ2 | 1120 | 4000 | 25 | 28 | 62 | 44 | 315 | 144 | 120 | 75 | 95 | 105 | 30 | 25.5 | 44 | 30 | 110 | 9.2 | 0.02 |

| PGCLZ3 | 2240 | 3550 | 30 | 38 | 82 | 60 | 355 | 174 | 140 | 95 | 115 | 130 | 30 | 18 | 40 | 30 | 155 | 16.4 | 0.04 |

| PGCLZ4 | 3550 | 2500 | 32 | 38 | 82 | 60 | 40 | 196 | 165 | 115 | 130 | 130 | 30 | 29 | 47 | 30 | 190 | 22.7 | 0.08 |

| PGCLZ5 | 5000 | 2500 | 40 | 56 | 112 | 84 | 400 | 224 | 183 | 130 | 150 | 150 | 30 | 18 | 43 | 30 | 300 | 36.2 | 0.15 |

| PGCLZ6 | 7100 | 2000 | 48 | 56 | 112 | 84 | 450 | 241 | 200 | 145 | 170 | 155 | 30 | 21 | 50 | 30 | 420 | 46.2 | 0.24 |

| PGCLZ7 | 10000 | 1700 | 60 | 75 | 142 | 107 | 450 | 265 | 230 | 160 | 190 | 180 | 30 | 19 | 50 | 30 | 630 | 68.4 | 0.43 |

| PGCLZ8 | 14000 | 1700 | 65 | 75 | 142 | 107 | 500 | 285 | 245 | 175 | 210 | 180 | 30 | 20 | 50 | 30 | 730 | 81.1 | 0.61 |

| PGCLZ9 | 18000 | 1600 | 70 | 75 | 142 | 107 | 560 | 314 | 270 | 200 | 225 | 200 | 30 | 25 | 60 | 30 | 770 | 100.1 | 0.94 |

| PGCLZ10 | 31500 | 1600 | 80 | 95 | 172 | 132 | 800 | 346 | 300 | 220 | 250 | 230 | 30 | 20 | 58 | 30 | 990 | 147.1 | 1.67 |

| PGCLZ11 | 40000 | 1400 | 100 | 120 | 212 | 167 | 800 | 385 | 330 | 260 | 285 | 260 | 30 | 21 | 64 | 40 | 1300 | 206.3 | 2.98 |

| PGCLZ12 | 56000 | 1400 | – | 120 | 212 | 167 | 900 | 442 | 380 | 290 | 325 | 280 | 30 | 21 | 72 | 40 | 2200 | 284.5 | 5.31 |

| PGCLZ13 | 80000 | 1400 | 140 | 150 | 252 | 202 | 900 | 482 | 420 | 320 | 360 | 320 | 30 | 22 | 70 | 40 | 3300 | 402 | 9.16 |

| PGCLZ14 | 112000 | 1200 | 160 | 180 | 302 | 242 | 900 | 520 | 465 | 360 | 410 | 360 | 30 | 23 | 85 | 40 | 4900 | 582.2 | 15.92 |

###

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by CX 2023-04-04

Gear Custom Coupling Flexible Fluid Flange HRC Spacer Pin Mh Rigid Nm Jaw Steel Chain Brake Standard Drum Wheel Rolling Shaft Steel Transmission Parts with ce certificate top quality low price

Product Description

Gear coupling flexible CZPT Flange HRC CZPT r PIN MH Rigid NM Jaw Steel chain brake standard drum wheel rolling shaft steel transmission parts

Ever-Power industry is one of the biggest couplings manufacturer in CZPT , have already exported lots of gear couplings, Jaw couplings, chain couplings etc.. to Japan, Korea, CZPT , USA …..

Flexible best Fluid Gear Coupling Flange HRC Spacer Pin Mh Rigid Nm Jaw Steel Chain Brake Standard Drum Wheel Rolling Shaft Steel Transmission Parts with ce certificate top quality low price

Product Description

Gear coupling flexible CZPT Flange HRC CZPT r PIN MH Rigid NM Jaw Steel chain brake standard drum wheel rolling shaft steel transmission parts

Ever-Power industry is one of the biggest couplings manufacturer in CZPT , have already exported lots of gear couplings, Jaw couplings, chain couplings etc.. to Japan, Korea, CZPT , USA …..

Fluid shop Gear Coupling Flexible Flange HRC Spacer Pin Mh Rigid Nm Jaw Steel Chain Brake Standard Drum Wheel Rolling Shaft Steel Transmission Parts with ce certificate top quality low price

Product Description

Gear coupling flexible CZPT Flange HRC CZPT r PIN MH Rigid NM Jaw Steel chain brake standard drum wheel rolling shaft steel transmission parts

Ever-Power industry is one of the biggest couplings manufacturer in CZPT , have already exported lots of gear couplings, Jaw couplings, chain couplings etc.. to Japan, Korea, CZPT , USA …..